Our Location

B319, 6433 Yinggang East Road,

Qingpu District, Shanghai

The Internet of Things (IoT) for elevators is a technology that uses sensors, communication modules, and cloud platforms to monitor the real-time operation status of elevators (such as current, vibration, faults, etc.), enabling remote monitoring, predictive maintenance, and intelligent management. Its core goal is to improve safety, reduce operation and maintenance costs, and minimize elevator downtime.

However, the installation difficulties of current sensors have led to slow promotion of the Internet of Things in elevators, and even many installed systems are rendered useless due to maintenance difficulties.

The Four Pain Points of Traditional Closed Circuit Current Sensors

1.Installation requires stopping the elevator, and the process is cumbersome

It is necessary to disconnect and connect, coordinate with the property management, owners, and maintenance parties, which takes time for approval and affects the normal use of the elevator.

2.Stable in extreme environments, complex construction, and high labor costs

Installation requires professional electrician operation, with an average time of 2-3 hours per unit and expensive labor costs.

3.High wiring risk

Easy to cause loose wiring, short circuits, and even secondary faults, increasing safety hazards.

4.Difficulty in maintenance and replacement

Once the sensor malfunctions, the elevator needs to be stopped and disassembled again, resulting in a high complaint rate from homeowners.

Result: Even with mature IoT technology, very few projects have actually been implemented, especially in high-end places such as hospitals and office buildings where installation is almost impossible. It has significant cost advantages among products with the same precision, supports bulk procurement, and assists in the rapid implementation of projects.

Why are there no reliable open milliampere current sensors on the market?

Technical bottleneck

●The magnetic field with milliampere level current (1mA~1A) is extremely weak and susceptible to environmental electromagnetic interference (such as frequency converters and wireless signals).

●Traditional open sensor magnetic circuit breakage leads to a surge in measurement error (error>actual signal), making it impractical.

Market situation

●The opening sensors launched by a few manufacturers are bulky, expensive (thousands of yuan/unit), and have high false alarm and missed alarm rates.

DEXIE Electronics’ Breakthrough Solution: Open ended Milliampere Current Sensor

Based on digital flux gate technology, DEXIE Electronics has successfully developed the world’s first high-precision, switchable and installable milliampere level current sensor, completely solving industry problems!

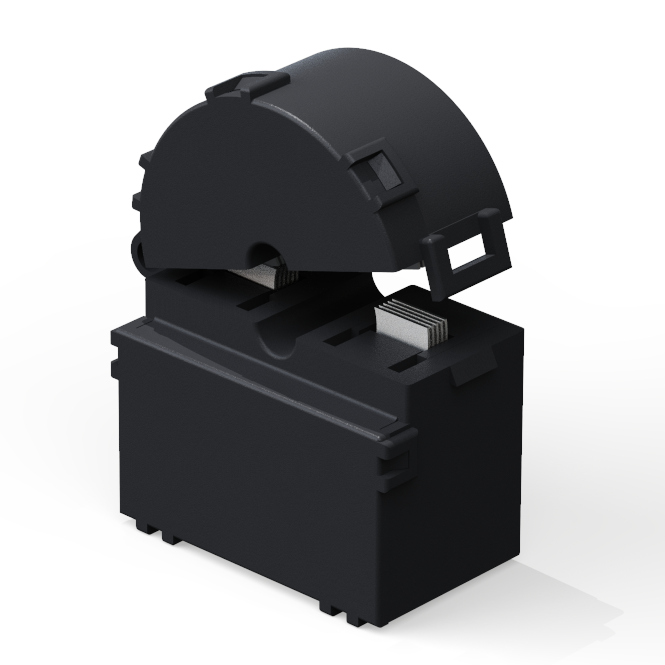

✅ No need to disconnect wires, no need to stop the elevator: direct buckle installation, 10 minutes to complete deployment, without affecting elevator operation.

✅ Can measure DC, AC, and pulsating DC.

✅ Single power supply 12V.

✅ Ultra precision range: measuring range of 1mA~1A, measuring leakage current as low as 1mA, with an error of less than ± 1%.

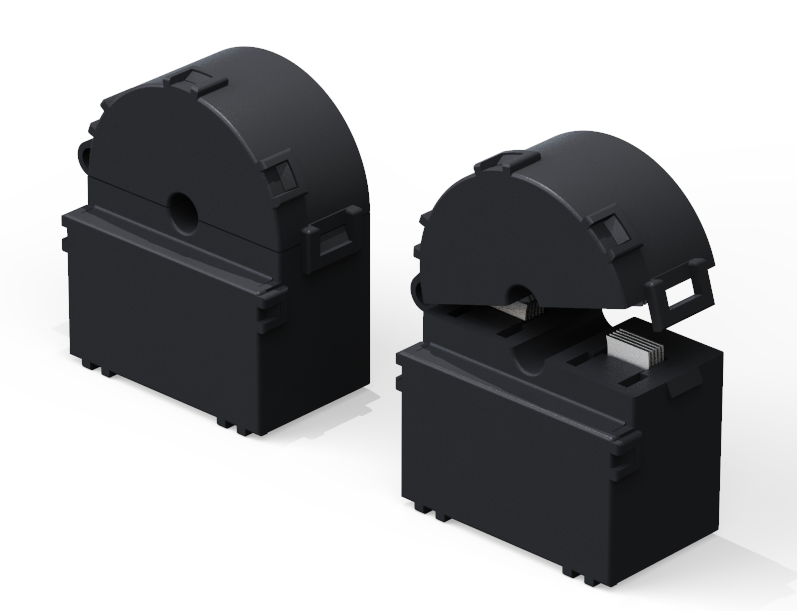

✅ Ultra small size: only palm sized, suitable for narrow electrical control cabinet spaces.

✅ Multiple output modes: RS485 (IoT docking), switch quantity (alarm), 0-5V (PLC access)

✅ Rapid response: < 100ms, real-time capture of transient faults.

Application value

●Property/maintenance company: Installation efficiency increased by 10 times, and operation and maintenance costs reduced by 50%.

●Elevator manufacturers: Enhance core competitiveness for IoT solutions and assist in bidding for high-end projects.

●Owner: Zero shutdown renovation of elevator, upgraded safety monitoring without feeling.