Our Location

B319, 6433 Yinggang East Road,

Qingpu District, Shanghai

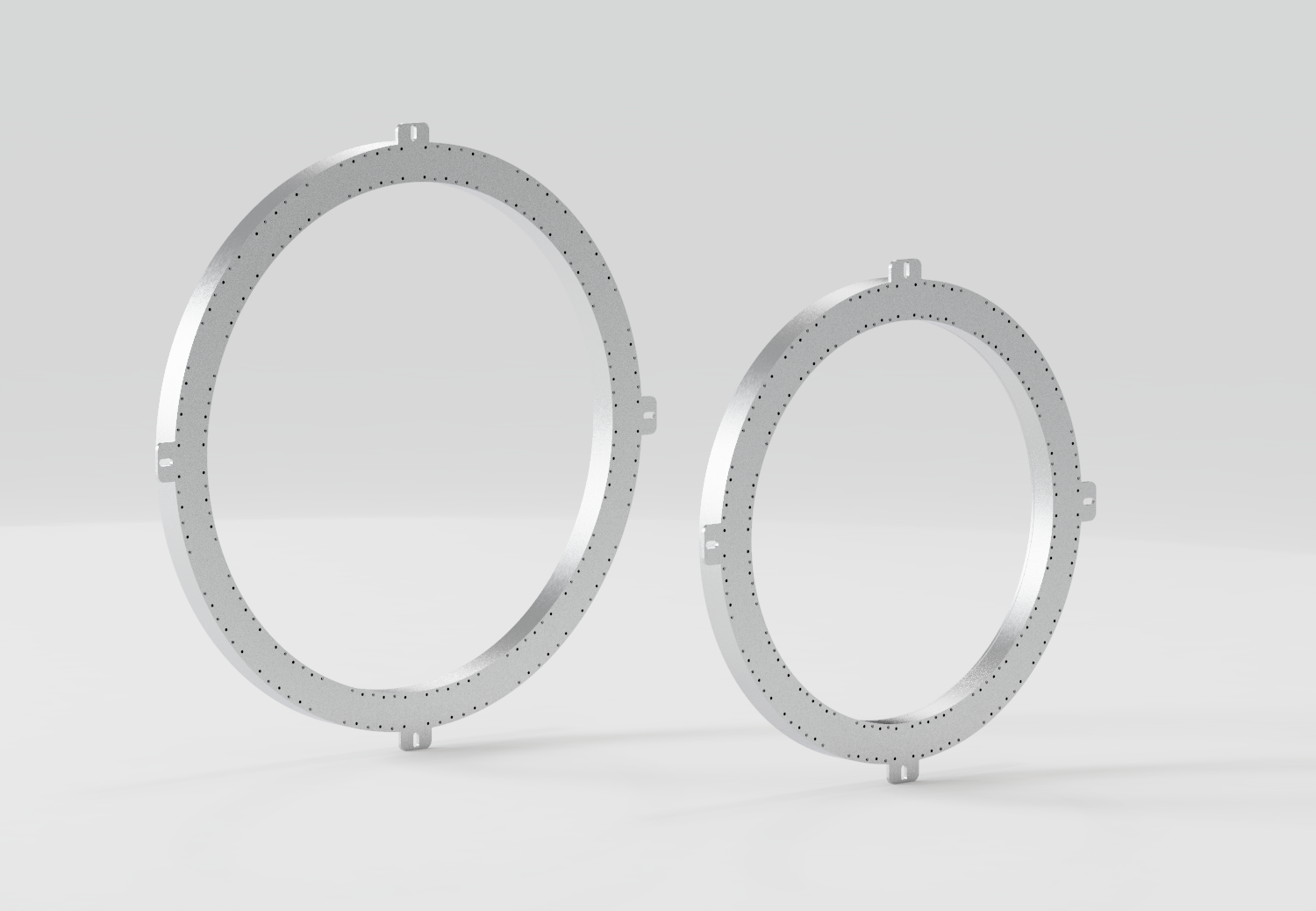

Item name: New energy wind turbine shaft current sensor

Industry challenge: Wind power has been booming in recent years, but there has always been a problem with the development of wind power. Due to the presence of shaft current, wind turbines and bearing components are often damaged, and the cost of replacing bearings is relatively high. Whether these damages are caused by shaft current or other problems has always been an unsolved mystery in the industry. The industry has always wanted to accurately measure the magnitude of shaft current, but suffers from the lack of a suitable current sensor. Many use Roche coils for measurement, but the data obtained is not reliable and lacks persuasiveness. (Roche accuracy is low)

In recent years, many wind power manufacturers have turned to DEXIE Electronics for help. DEXIE has conducted in-depth research on the mechanism of wind power shaft current generation, understood its damage to bearings, and spent six months measuring the approximate situation of shaft current on site. The magnitude of shaft current can cover tens of milliamps to hundreds of amperes, and the highest frequency can reach tens of KHZ. There is also significant electromagnetic interference in the surrounding area, and the unique structure of the fan significantly increases the measurement of bearing current.

Solution: Based on this situation, DEXIE has launched a shaft current sensor with a super large aperture, with a maximum aperture of 1.3 meters, and can measure a wide range of currents from 1 milliampere to 1000 amperes. The measurement bandwidth can reach up to 100KHZ, and the all-metal shell can shield the majority of electromagnetic interference. The full range accuracy can reach up to one thousandth. The measured data is accurate and reliable, and can provide real-time feedback on the shaft current.

Principle: Zero flux feedback high-precision mutual inductance principle